Mentor MP

25A to 7400A Two or four quadrant operation (regenerative)

24V – 480V / 500V – 575V / 500V – 690V

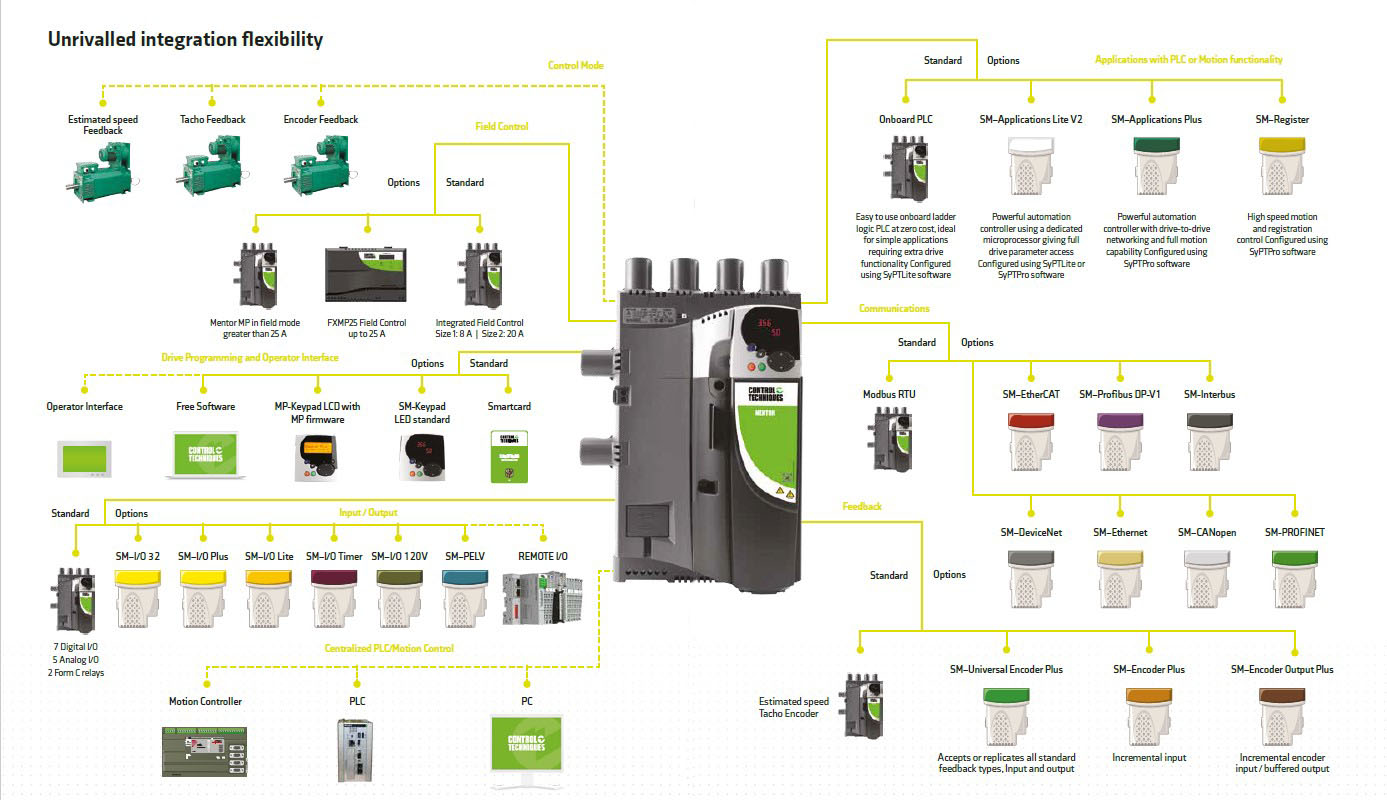

Mentor MP brings DC drive technology up to date, enabling existing and new DC motors to provide economic and productive service. DC drive technology remains cost effective, efficient and is relatively simple to implement. For new applications DC drive provides many advantages, especially for regenerative and high power applications.

Mentor MP Features

Greater motor field control

- Built in field controller as standard

- Gives excellent field control for the majority of DC motors

- Reduces the need for external components

Enhanced field control with FXMP25

- The FXMP25 may be controlled digitally by using a standard RJ45 connection, allowing set-up by standard drive parameters

- The FXMP25 can also function in standalone mode using its integrated keypad and display

Enhanced system design

- The heatsink cooling fans are intelligently controlled and only run when required, thus increasing reliability and reducing maintenance

- Eighteen different option modules allow customisation of the drive, including fieldbus, Ethernet, I/O, extra feedback devices and motion controllers

- The drive system designer is able to embed automation and motion control within the drive, eliminating communications delays that reduce performance

Fast set-up, configuration and monitoring

- Quick and easy to set-up

- Can be configured using optional removable keypads

- Advanced autotune features help you get the best performance from your machine

- PC software and Smartcard tools for rapid commissioning

- Intelligent networked system with CTNet

- Program inbuilt controller with SyPTLite

- Develop tailored solutions for applications modules with SyPTPro

- Option modules for all common Industrial Ethernet, fieldbus networks

Retro-fit projects

- Easy integration with your existing motor, power supply, application equipment and communication networks has been ensured from the design stage

- Mentor MP brings performance and possibilities to your application with minimum migration costs

Ease of migration

- Mentor MP has been designed so existing Mentor II customers can easily migrate to the new platform

- All power terminal locations and mounting points have been retained

- Mentor MP has a much smaller frame size than the 900 A Mentor II with paralleling options to offer high power density

- CT Soft has a built in migration wizard to assist with the transfer of drive parameters and programs

- Smaller cable requirements make connections within the cubical easier. Construction of a custom-made bus-bar is not required

Motor Field Control

- Built in field controller as standard in every Mentor MP

- Gives excellent field control for the majority of DC motors

- Reduces the need for external components

An external motor field controller is recommended when:

- The required field current is greater than that offered by the standard drive, up to 25 A. For example, older motors with low field voltages

- The field is required to be forced down more quickly than is possible with a standard half controlled field bridge

- Applications can be implemented with simple field current reversal, without armature reversal, if machine dynamics can still be met

Mentor MP Specification

-

- Models available for two or four quadrant (regenerative) operation

-

- 25A to 7400A, 24V – 480V / 500V – 575V / 500V – 690V

-

- Optional high-brightness LED or multi-language LCD keypad, simple configuration using plain text

-

- Modular parallel connection for higher power motor operation

-

- 12/24 pulse operation to minimize harmonics

-

- IP20 (NEMA 1) protection for size 1, IP10 (open chassis) for size 2A and 2B, and IP00 (open chassis) for size 2C and 2D for easy, low cost installation

-

- Integrated drive and motor protection for:

- Over current

- Over temperature

- Phase loss

- SCR/Thyristor junction temperature

- Feedback loss

- Field loss

- Armature open circuit

- Integrated drive and motor protection for:

-

- Internal field controller with intelligent field weakening means that for 90% of applications no additional external controller is required

- Frame size 1 to 8A

- Frame size 2 to 20A

- Flux control for enhanced open loop performance

- Internal field controller with intelligent field weakening means that for 90% of applications no additional external controller is required

-

- Optional FXMP25 external field controller for current fields up to 25A

- Digital link for field control from Mentor MP or Mentor II

- Standalone digital control mode for simple application

- Flux control for enhanced open loop performance

- Intelligent field weakening

- Field forcing – for high dynamic machine reversal

- Field reversal – low dynamic machine reversing using two quadrant main stack

- Optional FXMP25 external field controller for current fields up to 25A

-

- Mentor MP has a field control mode for fields requiring greater than 25A

-

- Serial port for Modbus RTU and PC communications

-

- 3 Universal option module slots, allowing Mentor MP to benefit from the solutions developed for Control Techniques market leading AC drive technology.

Each option slot allows:- High performance PLC and motion control

- Ethernet and Fieldbus communications

- Connectivity to additional feedback devices

- Additional I/O

- 3 Universal option module slots, allowing Mentor MP to benefit from the solutions developed for Control Techniques market leading AC drive technology.

-

- Galvanically isolated control

-

- Smartcard for drive parameter back-up and copying, allowing rapid installation and maintenance

-

- Integrated PLC as standard

-

- Standard software features for easy integration

- PID controller

- Motorized potentiometer

- Digital lock (Slave operation from master encoder)

- Standard software features for easy integration

-

- Open loop control using estimated speed advanced processing based on armature voltage and field flux feedback

-

- Closed loop control using

- Tacho-generator feedback for connection to traditional DC motor

- Incremental encoder feedback for higher accuracy and position control

- Optional SinCos, SSI, Hiperface and EnDAT connectivity for high performance applications

- Closed loop control using

- High performance control strategy

- 32 bit microprocessor

- 35μs current sampling time

- Speed controller and ramps update 250μs

- Autotune features for armature, field current loops and speed loop

Current ratings

The power ratings for the 480V, 575V and 690V configurations are shown below.

The continuous current ratings given are for a maximum ambient temperature of 40°C (104°F) and an altitude of 1000m (3,300ft). For operation at higher temperatures and altitudes de-rating is required. Overload of 150% for 30s is available with ambient temperature of 40°C (104°F) up to a maximum of 10 repetitions per hour.

Mentor MP 230V ratings

| MODEL | AC INPUT CURRENT | DC OUTPUT CURRENT | TYPICAL MOTOR POWER | ||

| CONTINUOUS | CONTINUOUS | 150% OVERLOAD | 240Vdc @ |

||

| A | A | A | hp | ||

| MP25A4(R) | 22 | 25 | 37.5 | 5 | |

| MP45A4(R) | 40 | 45 | 67.5 | 10 | |

| MP75A4(R) | 67 | 75 | 112.5 | 20 | |

| MP105A4(R) | 94 | 105 | 157.5 | 30 | |

| MP155A4(R) | 139 | 155 | 232.5 | 40 | |

| MP210A4(R) | 188 | 210 | 315 | 60 | |

| MP350A4(R) | 313 | 350 | 525 | 100 | |

| MP420A4(R) | 376 | 420 | 630 | 125 | |

| MP550A4(R) | 492 | 550 | 825 | 150 | |

| MP700A4(R) | 626 | 700 | 1050 | 200 | |

| MP825A4(R) | 738 | 825 | 1237.5 | 225 | |

| MP900A4(R) | 805 | 900 | 1350 | 250 | |

| MP1200A4(R) | 1073 | 1200 | 1800 | 350 | |

| MP1850A4(R) | 1655 | 1850 | 2775 | 550 | |

Mentor MP 480V ratings

| MODEL | AC INPUT CURRENT | DC OUTPUT CURRENT | TYPICAL MOTOR POWER | ||

| CONTINUOUS | CONTINUOUS | 150% OVERLOAD | @ 400 Vdc | @ 500 Vdc | |

| A | A | A | kW | hp | |

| MP25A4(R) | 22 | 25 | 37.5 | 9 | 15 |

| MP45A4(R) | 40 | 45 | 67.5 | 15 | 27 |

| MP75A4(R) | 67 | 75 | 112.5 | 27 | 45 |

| MP105A4(R) | 94 | 105 | 157.5 | 37.5 | 60 |

| MP155A4(R) | 139 | 155 | 232.5 | 56 | 90 |

| MP210A4(R) | 188 | 210 | 315 | 75 | 125 |

| MP350A4(R) | 313 | 350 | 525 | 125 | 200 |

| MP420A4(R) | 376 | 420 | 630 | 150 | 250 |

| MP550A4(R) | 492 | 550 | 825 | 200 | 300 |

| MP700A4(R) | 626 | 700 | 1050 | 250 | 400 |

| MP825A4(R) | 738 | 825 | 1237.5 | 300 | 500 |

| MP900A4(R) | 805 | 900 | 1350 | 340 | 550 |

| MP1200A4(R) | 1073 | 1200 | 1800 | 450 | 750 |

| MP1850A4(R) | 1655 | 1850 | 2775 | 700 | 1150 |

Mentor MP 575V ratings

| MODEL | CURRENT AC INPUT |

DC OUTPUT CURRENT | TYPICAL MOTOR POWER

|

||

| CONTINUOUS | CONTINUOUS | 150% OVERLOAD | @ 630 Vdc |

@ 600 Vdc |

|

| A | A | A | kW | hp | |

| MP25A5(R) | 22 | 25 | 37.5 | 14 | 15 |

| MP45A5(R) | 40 | 45 | 67.5 | 25 | 30 |

| MP75A5(R) | 67 | 75 | 112.5 | 42 | 50 |

| MP105A5(R) | 94 | 105 | 157.5 | 58 | 75 |

| MP155A5(R) | 139 | 155 | 232.5 | 88 | 100 |

| MP210A5(R) | 188 | 210 | 315 | 120 | 150 |

| MP350A5(R) | 313 | 350 | 525 | 195 | 250 |

| MP470A5(R) | 420 | 470* | 705 | 265 | 350 |

| MP700A5(R) | 626 | 700 | 1050 | 395 | 500 |

| MP825A5(R) | 738 | 825* | 1237.5 | 465 | 600 |

| MP1200A5(R) | 1073 | 1200 | 1800 | 680 | 900 |

| MP1850A5(R) | 1655 | 1850 | 2775 | 1045 | 1400 |

*For this rating at 575V, 150% overload time is 20s at 40°C and 30s at 35°C

Mentor MP 690V ratings

| MODEL | AC INPUT CURRENT | DC OUTPUT CURRENT | TYPICAL MOTOR POWER | ||

| CONTINUOUS | CONTINUOUS | 150% OVERLOAD |

@ 760 Vdc |

@ 700 Vdc |

|

| A | A | A | kW | hp | |

| MP350A6(R) | 313 | 350 | 525 | 240 | 300 |

| MP470A6(R) | 420 | 470* | 705 | 320 | 400 |

| MP700A6(R) | 626 | 700 | 1050 | 480 | 600 |

| MP825A6(R) | 738 | 825* | 1237.5 | 650 | 700 |

| MP1200A6(R) | 1073 | 1200 | 1800 | 850 | 1000 |

| MP1850A6(R) | 1655 | 1850 | 2775 | 1300 | 1600 |

* For this rating at 690V, 150% overload time is 20s at 40C ° and 30s at 35C °

Mentor MP Inputs and Outputs

| FUNCTION | QTY | I/O DEFAULT FUNCTION | RATING |

| Analog input 1 | 1 | Speed ref 1 | 10V± |

| Analog input 2

|

1 | Speed ref 2 | 10V(default), 0-20mA or 4-20mA± |

| Analog input 3 | 1 | Motor thermistor | 10V, 0-20mA, 4-20mA or Motor thermistor input (default)± |

| Analog output | 2 | Speed feedback output

Current feedback output |

10V(default), 0-20mA or 4-20mA± |

| Digital input | 3 | Run reverse input

Local/Remote select Jog forward input |

+24V |

| Digital input / output | 3 | At speed output

Reset input Run forward input |

+24V |

| Relay | 2 | Drive OK indicator | Normally closed |

| Drive enable | 1 | Drive enable | +24V |

| +24V External input | 1 | External 24V supply | +24V |

Conformance

- Humidity 95% maximum (non condensing) at 40°C (104°F)

- Ambient temperature -15°C to +40°C (5°F to +104°F), 55°C (131°F) with derating

- Altitude: 0 to 3000m (9,900ft), derate 1% per 100m between 1000m (3,300ft) and 3000m (9,900ft)

- Vibration: Tested in accordance with IEC 60068-2-64

- Mechanical shock tested in accordance with IEC 60068-2-29

- Storage temperature -40°C to +70°C (-40°F to +158°F)

- Electromagnetic immunity complies with EN 61800-3 and EN 61000-6-2

- Notch Immunity to IEC60146-1-1 class A

- IEC 61800-5-1 Electrical safety

- IEC 61131-2 I/O

- EN 60529 Ingress protection

- UL508C

- EN 61000-6-4 EMC – with optional EMC filters

- RoHS compliant

| MODEL | FRAME | ARMATURE CURRENT

(A)* |

FIELD

CURRENT (A) |

OVERALL DIMENSION | OPERATIONQUADRANTS OF |

||||

| 480V

EN / IEC cULus

|

575V

EN / IEC cULus to 600V |

690V

EN / IEC |

(W) Width |

(H) Height |

Depth (D) |

||||

| MP25A4(R) | MP25A5(R) |

1A

|

*25 | 8 | 293mm (11.54in) | 444mm (17.48in) |

222mm (8.74in)

|

2 and 4

|

|

| MP45A4(R) | MP45A5(R) | *45 | |||||||

| MP75A4(R) | MP75A5(R) | *75 | |||||||

| MP105A4(R) | MP105A5(R) | 1B | *105 | 293mm (11.54in) | 444mm (17.48in) |

251mm (9.88in)

|

2 and 4

|

||

| MP155A4(R) | MP155A5(R) | *155 | |||||||

| MP210A4(R) | MP210A5(R) | *210 | |||||||

| MP350A4(R) | MP350A5(R) | MP350A6(R) | 2A

|

*350 | 20 | 495mm (19.49in) | 640mm (25.20in) |

301mm (11.85in)

|

2 and 4

|

| MP420A4(R) | *420 | ||||||||

| MP470A5(R) | MP470A6(R) | 470** | |||||||

| MP550A4(R) | *550 | ||||||||

| MP700A4(R) | MP700A5(R) | MP700A6(R) |

2B

|

*700 | 495mm (19.49in) | 640mm (25.20in) |

301mm (11.85in)

|

2 and 4

|

|

| MP825A4(R) | MP825A5(R) | MP825A6(R) | 825** | ||||||

| MP900A4(R) | *900 | ||||||||

| MP1200A4 | MP1200A5 | MP1200A6 | 2C | *1200 | 555mm (21.85in) | 1050mm

*** |

611mm (24.06in) | 2

|

|

| MP1850A4 | MP1850A5 | MP1850A6 | *1850 | ||||||

| MP1200A4R | MP1200A5R | MP1200A6R | 2D | *1200 | 555mm (21.85in) | 1510mm (59.45in)

*** |

611mm (24.06in) | 4 | |

| MP1850A4R | MP1850A5R | MP1850A6R | 1850* | ||||||

*Current ratings are at 40°C with 150% overload for 30s.

**For this rating at 575V and 690V, 150% overload time is 20s at 40°C and 30s at 35°C.

***Height including optional fit exhaust duct cover is 1252mm (49.29in) for size 2C and 1712mm (67.40in) for size 2D.

7400A is achieved by parallel connection of Mentor MP drives

Mentor MP Keypads and parameter storage

|

Smartcard A memory device that can be used to back-up parameter sets and PLC programs, and copy them from one drive to another |

|

SM-Keypad SM-Keypad is a high brightness LED keypad for Unidrive SP (except frame size 0), Mentor MP and Affinity drives |

|

MP-Keypad MP-Keypad is a multi-lingual, hot pluggable, backlit LCD display |

Automation and Motion option modules

|

SM-Applications Plus SM-Applications Plus offers high performance programmable logic and motion control together with high speed I/O and CTNet, a high speed Fieldbus |

|

SM-Applications Lite V2 User programmable logic and motion control module for standalone drive applications or for when the drive is connected to a centralized controller via I/O or Fieldbus |

|

SM-Register A flexible, high performance solution for programmable motion requiring high speed registration features |

Communication option modules

|

SM-CAN User programmable CAN option module, allows the development of CAN protocols |

|

SM-CANopen CANopen interface supports various profiles including several drive profiles |

|

SM-DeviceNet SM-DeviceNET option module |

|

SM-EtherCAT Follower option module, for high performance servo applications |

|

SM-Ethernet Supports Ethernet/IP and Modbus TCP/IP and can generate emails. Provides high speed drive access, global connectivity and integration with IT network technologies |

|

SM-Interbus Interbus interface option module |

|

SM-LON LonWorks interface for building automation applications |

|

SM-PROFIBUS-DP Follower option module |

|

SM-PROFINET PROFINET is an Ethernet based industrial network protocol adapting Ethernet hardware and protocols |

Input and Output option modules

|

CTNet IO Flexible I/O system for remote connectivity with Control Techniques’ SM-Applications Plus and SM-Register option modules |

|

SM IO 24 V Protected Overvoltage protected I/O module |

|

SM-IO 120 V Module that provides digital I/O rated to 120Vac |

|

SM-IO 32 Extended digital I/O, adding 32 digital high speed bi-directional I/O points to the drive |

|

SM-IO Lite Extended I/O interface with reduced functionality |

|

SM-IO PELV NAMUR standard I/O interface with high speed I/O |

|

SM-IO Plus Extended I/O interface to increase the number of I/O points on a drive |

|

SM-IO Timer Extended I/O option module with real time clock |

Feedback option modules

|

SM-Encoder Output Plus Incremental encoder input and output option module that enables connection with external motion controllers |

|

SM-Encoder Plus Incremental encoder input option module |

|

SM-Universal Encoder Plus Additional combined encoder input and output interface supporting Incremental, SinCos, HIPERFACE, EnDAT and SSI encoders |

Mento MP Software

Control Techniques Windows-based software packages connect using Ethernet, CTNet, Serial or USB connections. Ethernet communications allow the drives to be accessed remotely, anywhere in the world.

Commissioning and monitoring software

Automation and motion programming software

Connectivity software

|

CTOPCServer – OPC compliant server CTOPCServer is an OPC compliant server for interfacing your own PC software with Control Techniques drives |

Đánh giá

Chưa có đánh giá nào.